Why hiring more people hasn’t solved productivity challenges—and how skilling is reshaping the furniture manufacturing workforce.

India’s furniture manufacturing sector—often described as a sunrise industry—continues to remain highly unorganised and constrained by a chronic shortage of skilled manpower. For many furniture SMEs, rising demand has translated into one instinctive response: hire more people. Yet, in practice, this approach has frequently backfired, resulting in declining quality, rising rework, and day-to-day operational instability.

These challenges formed the backdrop of a recent webinar organised by the Furniture &

Fittings Skill Council (FFSC) in association with the India Kitchen Congress (IKC). Titled Hiring Less, Training Better: Smarter Workforce Strategies for Furniture Manufacturers, the session brought together three India Kitchen Congress Awards 2025 winners—industry practitioners recognised for their on-ground impact—to discuss how furniture manufacturers can attract, train, and retain skilled manpower without over-hiring or inflating costs.

The panel comprised Padma Gupta, Director – HR and Customer Experience at Hafele India; Prasanth P, Vice President at FFSC; and Siva Prakash Alluri, Managing Director of Elemmentz Living.

The choice of panellists for this discussion was deliberate and rooted in demonstrated, on-

ground impact, not just designation or theory. Padma Gupta, winner of the IKC Skill Catalyst Award 2025 – Corporate (GOLD), represents an enterprise-led perspective on how

structured capability building, role clarity, and people systems can drive scalable growth

across complex organisations.

Prasanth P, recipient of the IKC Skill Catalyst Award 2025 – Individual (GOLD), brings deep,

hands-on insight into skilling frameworks, workforce deployment, and the practical realities

of training talent at scale across the furniture and interiors ecosystem.

Complementing these perspectives, Siva Prakash Alluri, whose company Elemmentz Living

won the IKC Tech Enablement in Kitchen Design & Sale Award 2025 (SILVER), offers the

critical SME-manufacturer lens—demonstrating how skilling, process discipline, and

technology adoption translate into measurable shopfloor outcomes.

Together, the three represent the full arc of the skilling conversation: strategy, execution,

and impact—making them uniquely suited to address the furniture manufacturing

workforce challenges facing SMEs today.

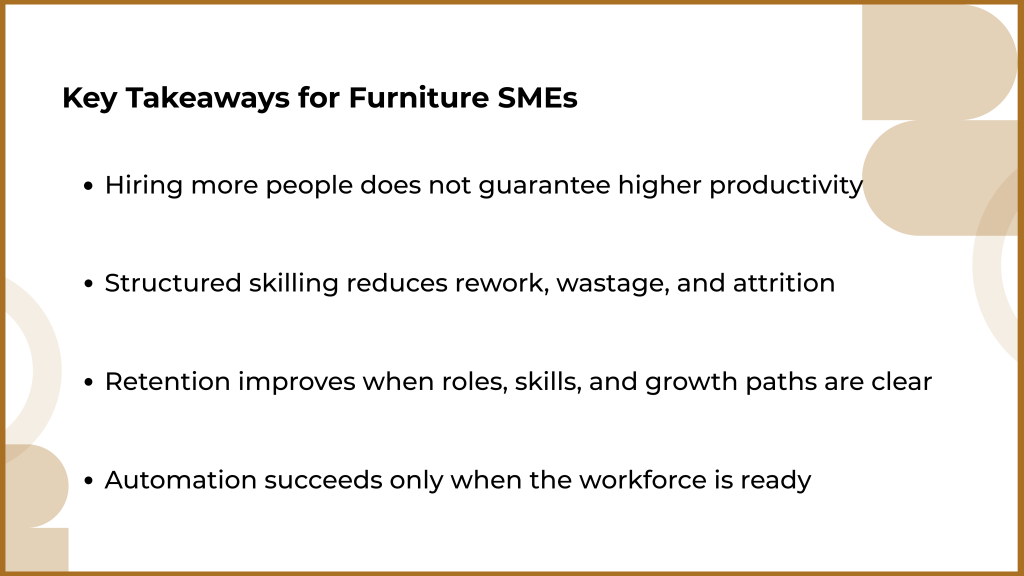

They argued that furniture SMEs must train better, not hire more.

What the Webinar Set Out to Address

The discussion focused on a core set of issues confronting the furniture manufacturing

workforce today: how SMEs can stabilise production with smaller, better-trained teams;

where businesses typically over-hire but under-skill; how structured training reduces

rework, wastage, dependency on a few ‘star’ workers, attrition, and last-minute firefighting; and how manufacturers can prepare their teams for incremental automation, even with limited capital expenditure.

The Hiring Paradox in Furniture Manufacturing

One of the biggest challenges facing the industry is the lack of a skilled workforce. But why

does this gap persist?

According to Padma Gupta, growing demand often forces manufacturers to hire quickly in

order to increase output—frequently compromising on skill quality in the process. The result is a swelling workforce that dilutes average capability and, paradoxically, reduces

productivity.

“Recruiting more workers does not necessarily translate into higher output,” Gupta noted,

pointing that the influx of inadequately trained personnel increases supervision load,

rework, and wastage.

Another factor exacerbating the problem is the industry’s limited appeal to new talent.

Furniture manufacturing, Siva Prakash Alluri observed, is “not yet seen as an aspirational

industry”.

“When an industry fails to attract a strong talent pool, what remains is largely a workforce

driven by compulsion rather than choice,” he said. “This is one of the biggest challenges we

face.”

Gupta echoed this concern, adding that the lack of pride and belonging within the workforce discourages skilled individuals from entering or staying in the sector.

Why Skilling Works Better Than Hiring in Furniture SMEs

Both panellists agreed that the answer lies not in hiring more people, but in skilling existing

teams more effectively. Furniture manufacturing, they emphasised, is both labour- and skill-intensive, while being acutely sensitive to quality.

To make training effective, Gupta stressed the need to standardise learning processes. “A

lot of individuality still exists in how tasks are performed,” she said. “If processes were

standardised and knowledge made easily accessible, it would significantly shorten the

learning curve and improve efficiency.”

Beyond technical capability, the speakers highlighted the importance of building a sense of

belonging within the furniture manufacturing workforce. This, they noted, plays a decisive

role not only in attracting talent but also in retaining it.

“What really makes people stay is the sense of connection and belonging they feel towards

the organisation,” Gupta said. “It’s also important for younger employees to understand the

purpose behind their work.”

Alluri illustrated this with examples from Elemmentz Living, where employees who joined as helpers progressed to senior shopfloor roles—including assistant factory managers—through sustained training and capability-building initiatives.

“A sense of insecurity is widespread in the industry,” he observed. “Continuous training and

reassurance are essential to change that mindset.” These measures, he added, have helped

significantly reduce attrition within his organisation.

“Hiring more people will not solve our problems unless we skill them properly,” Alluri said.

“While classroom training is important to understand the basics, learning cannot stop at

theory.”

Automation Without Skills: Why Machines Alone Don’t Solve the Problem

With automation increasingly shaping manufacturing globally, the discussion also addressed

why technology alone has not solved the sector’s skill gap.

“Machines alone will not solve the problem,” Alluri explained. “Without the right processes

and people, automation can actually add complexity.”

Gupta cautioned against indiscriminate capital investment. “Before investing in machines,

manufacturers must ensure they have people capable of using them effectively,” she said,

warning that mindless automation often leads to higher capex without commensurate

returns.

The panel agreed that people readiness must precede machine investments, particularly for

SMEs operating with tight margins.

Training as a Business Decision

The discussion concluded with a clear consensus: structured, continuous training is essential—not just to improve the furniture manufacturing workforce quality, but to build

learning systems that are scalable and adaptable across the industry.

“Skilling is not an HR activity,” concluded Prasanth P, Vice President at FFSC. “It is a business decision.” He also underscored the importance of industry-led skilling infrastructure, highlighting the FFSC’s strong nationwide network of skilling academies. He emphasised that these academies are not merely training centres, but practical growth enablers that furniture and panel manufacturing SMEs should actively leverage—to access job-ready talent, shorten learning curves, and build scalable and future-ready operations without inflating manpower costs.

For furniture SMEs, the message was unambiguous. Productivity, stability, and scalability

will not come from expanding headcount alone. They will come from investing in skills,

building clarity of roles, and creating organisations where people capability grows alongside

machines and markets.

ALSO READ