To enjoy the fruits of demographic dividend and for meeting the demand of changing dynamics of the industry, the success of Skill India mission is critical. We explain here how skilling, or lack thereof, is going to impact the building products sector and how the industry is responding to this imperative. We also profile the ‘skill builders of the industry’, leaders who are making a difference for their sectors through their vision

There is an incremental human resource requirement to the tune of 120.79 million across sectors in the period between 2013 and 2022, as per the projection of Ministry of Skill Development and Entrepreneurship. Building, construction and real estate sector will account for 31.13 million (about 25%) of this surge in requirement. Add to this the changing industry landscape wherein the process of manufacturing and designing is changing with a lot of activity being automated to bring in standardisation and to increase productivity. In fact, experts believe that the next level of industrial revolution will be in IIoT or Industry 4.0. Therefore, even the existing workforce needs skill upgradation. And, as the government pushes for Make in India, availability of skilled manpower becomes imperative.

The availability of manpower is not a concern for India as about 66% of the nation’s population will be in the working age group by 2022. However, paucity of highly trained workforce and non-employability of large sections of the conventionally educated youth poses a hindrance for India to enjoy demographic dividend. As per a NSDC report, only 4.69% of the total workforce in India has undergone formal skill training as compared to 68% in UK, 75% in Germany, 52% in USA, 80% in Japan and 96% in South Korea.

Skill India Mission

- Create a demand for skilling across the country

- Correct and align skilling with required competencies

- Connect the supply of skilled human resources with sectoral demands

- Certify and assess in alignment with global and national standards

- Catalyse an ecosystem wherein productive and innovative entrepreneurship germinates, sustains and grows, leading to creation of a more dynamic entrepreneurial economy and more formal wage employment

To address this issue, the government revamped the existing skill development policies formulated by NSDC in 2009 and established a separate ministry – Ministry for Skill Development & Entrepreneurship, in November 2014, to take this on a mission mode – Skill India Mission. The ministry has an objective of streamlining previous skill development initiatives and creating an appropriate ecosystem that facilitates imparting employable skills to its growing workforce over the next few decades. The challenge pertains not only to a huge quantitative expansion of the facilities for skill training, but also to the equally important task of raising their quality.

Framework

A proper institutional mechanism has been put in place in order to drive this Skill India agenda. As defined in the MoSDE booklet ‘National Skill Development Mission – A framework for implementation’, “Key institutional mechanisms for achieving the objectives of the Mission have been divided into three tiers. The Mission will consist of a Governing Council at apex level, a Steering Committee and a Mission Directorate (along with an Executive Committee) as the executive arm of the Mission. Mission Directorate will be supported by three other institutions: National Skill Development Agency (NSDA), National Skill Development Corporation (NSDC), and Directorate General of Training (DGT) – all of which will have linkages with the Mission Directorate to facilitate smooth functioning of the national institutional mechanism. These three agencies would continue to lie under the umbrella of Ministry of Skill Development & Entrepreneurship.”

At State level, states will be encouraged to create State Skill Development Missions (SSDM) along the lines of National Skill Development Mission with a Steering Committee and Mission Directorate at State level. States will in turn be supported by District Committees at the functional tier, the policy paper noted.

At State level, states will be encouraged to create State Skill Development Missions (SSDM) along the lines of National Skill Development Mission with a Steering Committee and Mission Directorate at State level. States will in turn be supported by District Committees at the functional tier, the policy paper noted.

NSDC is the implementation arm and is given the task of creating a government, industry and academia interface. This PPP initiative has an aim to skill a minimum 500 million people by the year 2022. To better streamline the initiative, sector-specific skill councils have been formed. These sector-specific skill councils are autonomous industry-led bodies that drive the skill development training in India. At present, there are 40 sector skill councils (SSCs) and 267 training partners associated with NSDC, with more than 2,500 training centre in over 350 districts across the country.

Industry Participation

For a skilling mission to be successful it should be complemented by commensurate creation of jobs in the primary, secondary and tertiary sectors. Thus, understanding the importance of industry participation, the government has entrusted the job of skilling with industry-led sector skill councils. For the building materials industry, there are four sector skill councils which are working in different domains. While the plumbing sector comes under Indian Plumbing Skill Council (IPSC), the relevant sector council for the construction segment is Construction Skill Development Council of India (CSDCI). The furniture and fittings sector is covered by the Furniture and Fittings Skill Council (FFSC). And, for paints and coatings there is Paints and Coatings Skill Council (PCSC).

SSCs, as industry-led bodies, have been strengthened by making them more representative, expanding their outreach and increasing their efficiency. The development of National Occupational Standards (NOS) and Qualification Packs (QPs) for various job roles in a sector will remain the key responsibility of the SSCs. All these sector skill councils act as a bridge between the industry and trainees for skilling.

Industry-led Skilling Activities

According to the Indian Plumbing Association (IPA), only 20-25% of the plumbing segment is organised. Both the industry association as well as the manufacturers themselves has invested in skill development initiatives.

The IPA in collaboration with International Association of Plumbing and Mechanical Officials (IAPMO) and Green Plumbers USA (GPUSA) had launched in 2010 Green Plumbers India (GPI) – an innovative national training and accreditation programme that assists the individuals in understanding their role in protecting environment and public health. Since then, GPI workshops across the country have created Accredited Trainers and Specialists to spread the message of water and energy conservation.

While the focus on the former programme was on sustainable plumbing practices, IPA and IAPMO have also jointly launched a nationwide programme to impart plumbing training and education – Plumbing Education to Employment Programme (PEEP). “Overall, PEEP is a well-structured education and training programme to create Design Engineers, Construction Managers, Master Plumbers and Apprentice Plumbers with skill levels comparable to their counterparts in the developed countries,” informed managing director of IAPMO India Neeta Sharma, in an earlier interaction with Sourcing Hardware last year. Additionally, IPA and IAMPO have also partnered with the government of Kerala to provide plumbing training to students enrolled under the state’s Additional Skill Acquisition Program (ASAP).

The manufacturers of plumbing products have also come forward. They have more than one reason to do so, as lack of quality plumbers can not only impact the quality and service of their superior products but importantly, hurt their image due to faulty installations. Naturally, pipe manufacturers as well as sanitaryware and bath fitting manufacturers have invested in skill development. Some even has extended it beyond plumber meets and training, and institutionalised such skill development programmes as a part of their CSR activities.

At a Glance

- 1.04 crore youth have been trained under Skill India Mission in FY15-16; 36.8% increase from last year

- 60% of this training is directly under Ministry of Skill Development & Entrepreneurship; rest 40% comes under other central ministries

- More than 20 lakh trained under PMKVY launched in July 2015; 40% of trainees are women

- Number of ITI increased to 13,105 in May 2016 from 10,750 in May 2014; will reach 18,000 by September 2016

- Setting up model skill centre in each of the over 500 districts in the country; to be operational by March 2017

Source: Ministry of Skill Development & Entrepreneurship

For instance, German bath-fiitings major Grohe runs two Grohe Jal academies, in Mumbai and New Delhi, under its Grohe Dual Tech programme. Both academies train young people from economically challenged backgrounds in their regions by imparting a high-quality training programme in certified plumbing. The programme address the dual need of the industry – on one hand it supports the youth with skill development, while on the other it fills the skilled-labour supply gap.

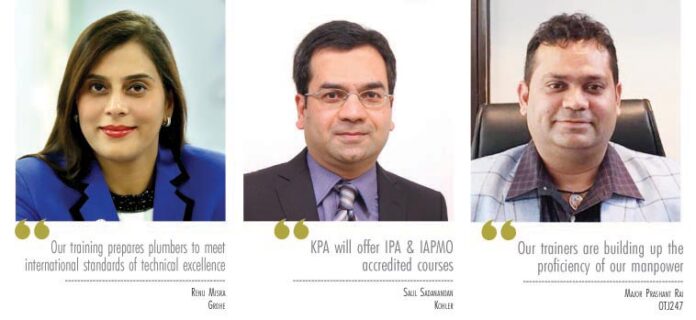

Renu Misra, managing director, Grohe India says, “We see high demand for skilled workers in the sanitaryware and real estate space in India. The country continues to have a large number of unemployed youth. We are determined to plug this gap and create opportunities for ambitious young people. Training at the Grohe Dual Tech gives them the recognition of certified plumbers from the academy and subsequently find employment. The training also prepares them for meeting international standards of technical excellence while serving their customers.”

In a similar move, Kohler India, last year, inaugurated Kohler Plumbing Academy in collaboration with SNS Foundation to impart plumbing training. The project has been undertaken as a CSR initiative of Kohler in India, wherein complete support shall be extended to the SNS Foundation Building in Gurgaon for the purpose of educating underprivileged youth and enabling them to qualify for employment opportunities in the plumbing field.

Salil Sadanandan, managing director, Kohler Kitchen and Bath, India, informed during the launch event that the academy will offer two certification courses in plumbing which are accredited and certified by IAPMO and IPA. While the Trained Master Plumber (TMT) certified plumber is eligible for supervision of plumbing activities at site, the Trained Apprentice Plumber (TAP) is certified for doing plumbing activities at site. There is flexibility on required minimum educational qualification for enrolment of the students for the apprentice programme, and even registers students who have discontinued studies post their initial schooling. Academy trainers will receive one week training at IAPMO’s Bengaluru and Pune centres. “The SNS Foundation will help mobilise students from underprivileged areas for enrolment in Trained Apprentice Plumber course. The course duration being 45 days, KPA plans to take in strength of 15 students per batch with an annual plan of taking in 70 students,” informed Sadanandan.

The home services sector too is doing its bit to bring about change in the way blue collar professionals work. They are trying to organise the sector and bring in standardisation of service delivery and quality. On the challenges of finding the right talent and getting the skilled manpower on board, Major Prashant Rai, founder and CEO of OTJ247.com (formally Onetimejobs.com) commented, “We have in-house capabilities for grooming servicemen. Plus, we have tied up with other organisations that impart technical training. Besides, through a very selective recruitment process we are putting a premium on behaviour and proficiency.”

The construction chemical major Pidilite is particularly known for its nationwide skill development initiatives for architects, contractors and the plumber community. The company has recently tied up with Indian Plumbing Skill Council (IPSC) for organising workshops for plumbers. “This initiative is aimed at providing training to plumbers and equipping them with the required skill sets,” said Vishal Malhan, VP–sales & marketing, CP-MNT division, Pidilite Ltd. The company initiated the first skill development programme for the plumbing fraternity in Mumbai under the ‘Pradhan Mantri Kaushal Vikas Yojana’ (PMKVY). Over 50 plumbers have already been trained and certified under this programme. Pidilite aims to train over 1,000 plumbers across country in this fiscal year.

The training and skill development programmes for the architects and masons are of paramount importance for the growth of the industry. Sanjay Bahadur, global CEO-construction chemicals at Pidilite opined, “Although knowledge about right accessories is essential, there is also a critical need for training the contractors and masons.” Highlighting the initiatives taken by Pidilite, Bahadur informed, “To resolve the issue of inadequate knowledge and untrained applicators, Pidilite has set up the Dr Fixit Knowledge Centre at Kochi to demonstrate the correct waterproofing techniques and provide practical training to deal with real life challenges. The response has been very good and we are planning to open more of such centres in other cities too. Pidilite also runs a non-for-profit organisation called Dr Fixit Institute, which imparts knowledge about the best construction practices in the industry to the ACE community and students of Civil Engineering.”

The training and skill development programmes for the architects and masons are of paramount importance for the growth of the industry. Sanjay Bahadur, global CEO-construction chemicals at Pidilite opined, “Although knowledge about right accessories is essential, there is also a critical need for training the contractors and masons.” Highlighting the initiatives taken by Pidilite, Bahadur informed, “To resolve the issue of inadequate knowledge and untrained applicators, Pidilite has set up the Dr Fixit Knowledge Centre at Kochi to demonstrate the correct waterproofing techniques and provide practical training to deal with real life challenges. The response has been very good and we are planning to open more of such centres in other cities too. Pidilite also runs a non-for-profit organisation called Dr Fixit Institute, which imparts knowledge about the best construction practices in the industry to the ACE community and students of Civil Engineering.”

Samir Surlaker, president of CCMA and managing director of MC Bauchemie, had shared with Sourcing Hardware in an earlier interaction, “Of course, one of the main objectives of our seminars and CCMA is to create trust in end users by creating standardisation and transparency. To take this initiative to the next level, training programmes would be held all over India for applicators, because application is a very important aspect of the very success of waterproofing and repair systems.”

He had added, “In addition, a handbook is planned on the correct usage of construction chemicals in collaboration with Indian Concrete Institute. Attempts are already on way to introduce technical topics in the academic syllabi. Training programmes are in advance stages of design. These roving seminars will be taken to rural areas as well as engineering colleges. Another initiative is to open up local chapters all over India. A further idea was to get a marking on construction chemicals to increase the confidence of the end user.”

Ronak Kumar Vijayvargiya, managing director of MD Brassware Pvt Ltd, which sells its door handles and locks under the brand name of Aarkay Vox, opined, “Due to improper installation of products by carpenters, we as a company and our end customers have suffered a lot.” However, he believes that with the government’s focus on skilling, the scenario is improving. The company has also tied up with skill centres and is giving training support to carpenters.

He added, “We are connecting with lock technicians and carpenters through our installation videos and telephone support across India. At MD Brassware developing new designs through innovation and technology is an ongoing process. At the same time we also provide diagram support, telephone and video support to facilitate easy and correct installation by technicians. In fact, our customer care number has a dedicated extension for installation support, and on our website we have uploaded videos of product installation for making this learning hassle free.”

Skilled masons are of paramount importance to the tile companies. The functionality and quality of tiles get hampered due to improper installation, besides bringing a bad name to the brand. Abhishek Somany, managing director of Somany Ceramics opined, “The construction industry lacks sufficient masons, resulting in a slowing of construction activity and increasing the overall cost of projects, posing a major challenge to India’s infrastructure development plans. The tile laying sector is not organised and the tilers are not formally trained in our country. This makes the consumer wary of dealing with the laying activities. In spite of the fact that India produces world class tiles in terms of technical parameters, when it comes to laying of tiles our tilers are abysmally ill-trained and non-competent, leading to poor quality of laying, shabby finish, lots of wastage of material and time.”

Somany Ceramics has launched a skill development initiative called Tile Master in 2010, as part of its CSR activities with the aim of enhancing tile laying skills of masons. “The other important and strategic purpose was to contribute in the growth of tile industry by way of creating a pool of expert masons so that world class tiles being produced in India should be laid perfectly in finish and aesthetics. This would ensure satisfied customers having high level of preference for tiles in the future,” added Somany.

Detailing on the course, he shared, “Considering the practical nature of the course, 70% of the course hours is dedicated to practical hands-on training and practice of using the tools. The course allows the participants to achieve and develop the professional skills necessary to perform the various tasks of tile laying with the desired skill and safety. Demonstrative methods are used to teach handling of most advanced tools sourced from the world over. Most advanced ergonomically designed tools are used in the school for tile laying operations.”

Detailing on the course, he shared, “Considering the practical nature of the course, 70% of the course hours is dedicated to practical hands-on training and practice of using the tools. The course allows the participants to achieve and develop the professional skills necessary to perform the various tasks of tile laying with the desired skill and safety. Demonstrative methods are used to teach handling of most advanced tools sourced from the world over. Most advanced ergonomically designed tools are used in the school for tile laying operations.”

K M Pai, executive director, Orient Bell opined, “Lots of people waste the tiles by not laying them properly. On every box of tiles, we write the instructions. Additionally, we regularly conduct mason meets. We call them for just half a day. We give them training through audio and visual means as well as via practical demonstrations by other masons. Once in a while we also call Italian technicians to do the demonstrations. The main focus of these trainings is proper use of various tools and machines – the simple and affordable ones. One of the key learning in these training sessions is how proper use of equipment can increase the earning potential.”

In nutshell, the industry and government are working in unison to create a pool of skilled workforce. The focus on skilling has become imperative with the changing dynamics of the industry and to meet the incremental human resource requirement. India has the potential to not only fulfil the internal demand but also develop itself as a supplier to the world. But for that to happen, a change of mindset is also necessary, especially in the blue collar profession. The government has initiated communication to generate awareness and attract youth to inculcate skills. However, for Skill India to be really successful, active participation from the youth is warranted!

Mrinmoy Dey

')}